Using iron and wood as primary materials for any structure gives you the advantage of strength and durability coupled with a natural finish. Attaching wood to a wrought iron fence demonstrates this ideal combination. We have researched everything you need to know so that you can begin with your project!

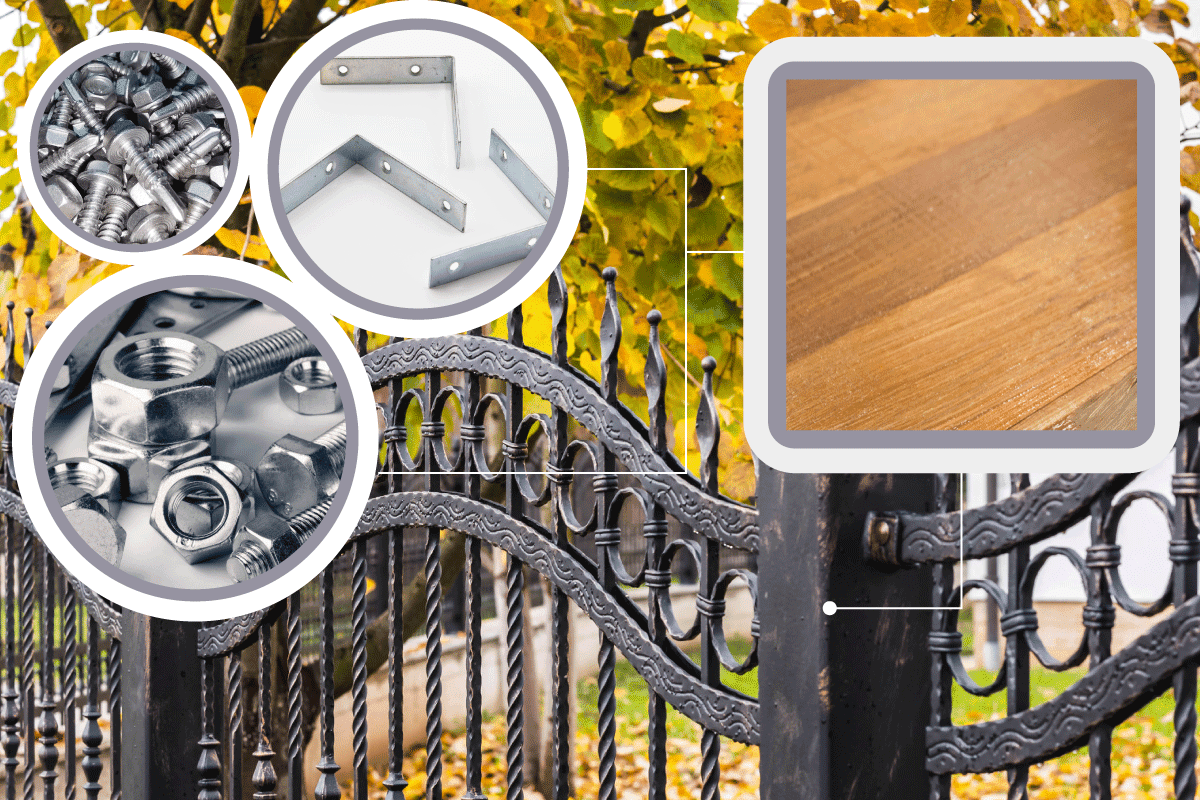

Adding wood to a wrought iron fence increases privacy and enhances appearance. There are several ways to achieve this. You can use screws, bolts, brackets, or mounting blocks to fasten wood to metal.

A step-by-step method is needed to complete this undertaking. But don't fret! This article includes the methods, materials, wood options, and other pertinent information to assist you in the process.

How to affix wood to metal?

Depending on the design and structure of your existing fence, the respective surfaces determine the process or method involved. Wood slats or panels are flat and relatively easy to affix. The contour, size, and shape of the iron fence would dictate what fasteners need to be used.

Direct Method

If the rails of your fence are flat and wide enough, the wood panels can be bolted or secured with screws directly into the metal.

After you have prepared the wood to the desired height and width, plot the general layout of the panels. You can either attach them with gaps for ventilation or directly side by side for better privacy.

Carefully measure the placement of the holes for the bolts or screws making sure the location in the wood and metal coincide.

Take note of the thickness of the wood and choose the appropriately sized fastener, there should be enough overlap for the bolt or screw to support the panel. Drill the holes and attach the boards securely. Use galvanized or rust-proofed materials to prolong the life of the fastener and avoid having to replace them regularly.

Brackets

Some wrought iron fences are designed with thin or irregularly shaped rails and spires rendering the area of surface contact too small. The best way to resolve this is with the use of metal brackets.

You can weld a three-inch wide, one-fourth inch thick flat bracket spanning the length of the fence from one post to the next.

This would serve as your horizontal rail, a top, the middle and the bottom one will secure the boards sufficiently. Drill the holes on both wood and metal, again carefully measuring to make sure they fall on the same spot. You can now proceed to bolt or screw on the wooden panels.

Mounting Blocks

A mounting block is an implement made of metal or wood designed and functions to attach a flat-surfaced material to a rounded object. It is even on one side and concaves on the other.

If you plan to affix wood to a metal post, you might fabricate or purchase a mounting block compatible with the curve of the support and, on the opposite side, an area with sufficient contact to support the panel. Predrill the holes, attach the blocks to the posts then connect the wooden boards.

Secure the screws or bolts tightly to prevent the panels from shifting, loosening, or falling off altogether.

Wood Panel Options

Since you intend to add wood to your metal fence, the following are the best choices for panels or boards:

1. Redwood

Redwood is an excellent choice for outdoor structures due to its strength and durability. It is naturally resistant to weather and decay and can withstand the elements.

Redwood is lighter than most lumber making it easier to saw, cut or drill. Due to its advantages, it results in higher demand, and consequently, becomes one of the most expensive materials in the construction industry.

2. Cedar

Cedar shares the general characteristics and advantages of redwood. It is less expensive but relatively softer, making it susceptible to dents, cracks, and warping over time. To maximize and prolong its lifespan, cedar has to be sealed and stained regularly.

3. Pressure Treated Pine

Since it is strengthened with chemicals, pressure-treated pine is also a good option. In terms of durability, it is comparable to some hardwood but at a much lower cost. Some varieties of pine however shrink or expand depending on the weather, so it is best to provide slight gaps between panel boards.

4. Brazilian Walnut

This type of walnut is imported from South America. Strong and highly durable, it can last as long as 40 years even when untreated. Due to its density, it does not crack, warp, dent, or decompose for long periods. The only disadvantage is that it may be hard to find and cost as much as composite wood materials.

Note that most woods cracks or split when punctured so always predrill the holes for the fasteners.

Paint or Stain Wood

Wood is structurally weaker than metal, making it more susceptible to environmental elements. It could, however, be protected and strengthened to prolong the usage and lifespan.

Painting your panels automatically provides a layer of weatherproofing and moisture resistance, and insect infestation. If you want to preserve the natural grain finish of the wood, wood stain is the best way to accomplish this.

Paint

Clean and sand the wood panels thoroughly to achieve an even, uniform surface. Always use a primer coat that prevents mold and mildew, protects wood from ultraviolet light and acts as an adhesive to the paint, and prolongs its color, shine and finish.

Apply your paint color of choice, let dry, and determine if an additional layer is necessary. Acrylic-based paints work best with outdoor applications, are easier to work with, and are less complicated to use.

Wood Stain

If you prefer to preserve the natural appearance of the wood, a clear wood stain finish would be the best way to accomplish this. First, apply a sealant that protects the material from moisture, then add an exterior varnish topcoat to enhance the appearance of your panels.

Sealants prevent early decay and wood deterioration while a few layers of varnish will afford extra protection and accentuate the beauty of the wood panels.

Is there another alternative to wood panels on wrought iron fencing?

Metal Boards or Panels

Metal boards or panels are materials that can also be used to add privacy to your wrought iron fence. They are more durable and hard-wearing simply because of their interior composition.

Rust or corrosion is the only drawback of this type of paneling. However, you can prevent oxidation by applying paint to the aforementioned items.

Privacy Mesh

Privacy mesh functions as a visual barrier and can be installed on your wrought iron fence for additional concealment. It is actually made of durable netting material.

Plants or Shrubs

If you wish to enjoy the beauty of your wrought iron fence, simply make use of plants or shrubs either on the outside or the inside of your property in order to have additional privacy.

In Conclusion

Wood and iron, when combined to construct fences allow you to benefit from their respective characteristics and advantages. The strength of metal coupled with the natural finish of wood results in a durable and attractive enclosure. We hope the article aided you in the various regards needed to accomplish the process.