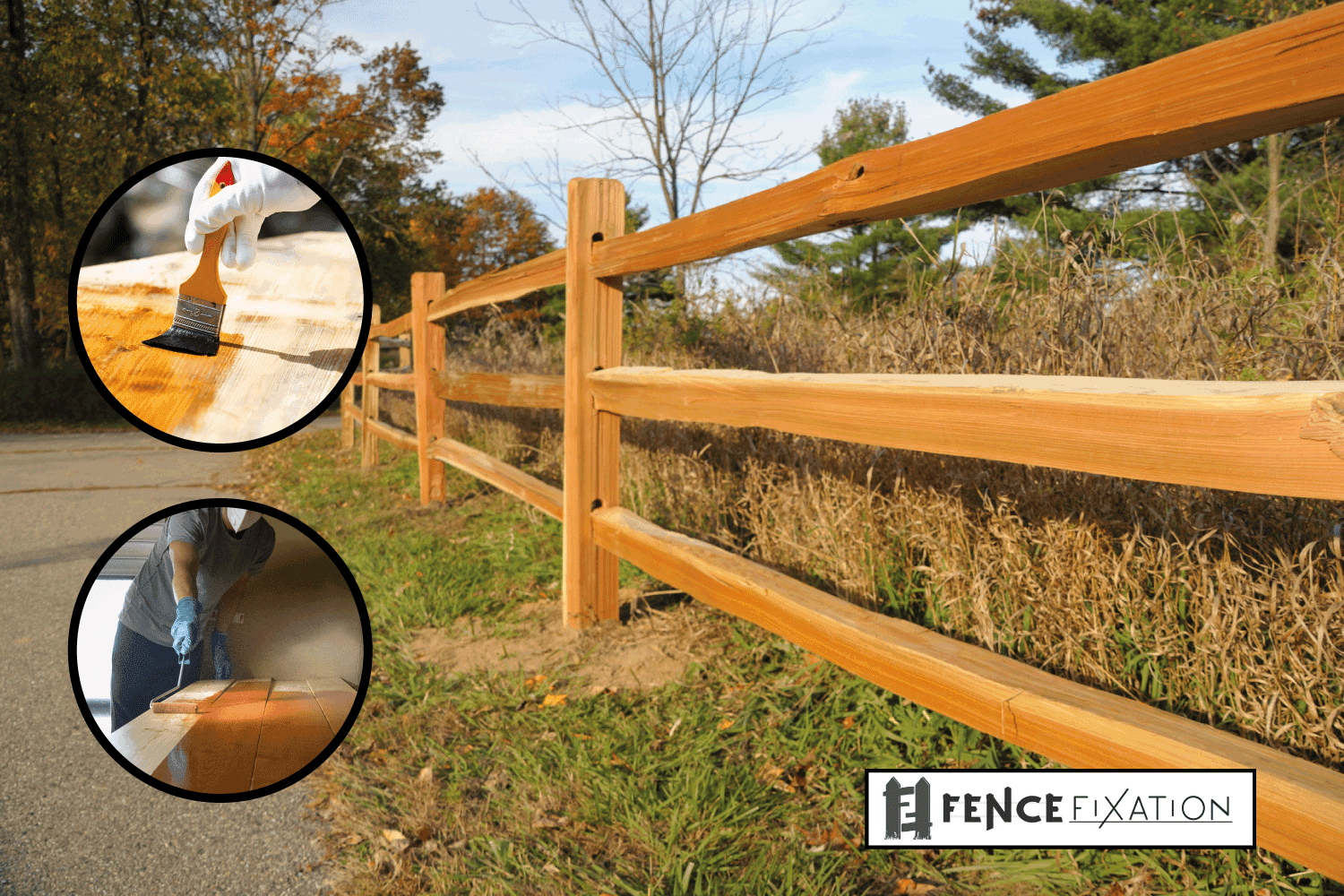

Split-rail fences are made from wood and used outdoors to enclose and demarcate large areas. They are exposed to the elements and take a beating from the environment. Would it be a good idea to treat a split-rail fence? This article aims to address important facts and considerations regarding this matter by sharing the answers we've found on this topic.

Traditional split-fence wood like cedar or pine may possess natural resistance to the elements but it is still recommended to treat them with preservatives. Regular staining is actually recommended as part of its maintenance.

A comprehensive discussion regarding the treatment agents, stains, application, and other important aspects of split fencing is included in the text below. Stick with us, you'll find this most helpful!

What Is A Split-Rail Fence?

Split-rail fences are a type of barrier made from rot-resistant wood. Felled trees like chestnut or cedar were cut into 10 to 12-foot logs. The timber was split into halves, quarters, and eighths to produce fence rails, hence the name.

Historically, it emerged in America during the colonial period. The abundance of timber from thickly wooded areas made split fencing the evident material and structure for various purposes.

Due to the cost and scarcity of hardware at the time, the first split fences were constructed simply by stockpiling rails and securing them between posts.

Split-rail fencing is still popular today due to its traditional American look and appeal. Different modern materials that are durable, easy to install, and maintenance-free are available on the market.

Some homeowners stick to the original split fencing wood like cedar, oak, or pine. These types of lumber are naturally weathered and durable, but there are ways to strengthen them even more and prolong their lifespan. Read on and may you find the article relevant.

Treatment Agents

There are numerous ways you can beautify, strengthen and prolong the life of your split-rail fence. Natural agents, preservatives, and wood stains are among the ways to accomplish this.

1. Oils

Linseed Oil

Linseed or flaxseed oil is one of the most traditional natural finishes used on wood. It is derived from the flaxseed plant and processed in different ways for several uses.

The substance seeps deep into the wood grain and protects it from moisture, rotting, and surface damage. It produces a glossy appearance that enhances the beauty of the wood. Linseed oil has numerous other applications but as a wood additive, it is available in raw, boiled, or polymerized form.

Raw Linseed Oil

Raw linseed oil is the pure and natural form of the substance, since no chemical agents are present, it is non-toxic and environmentally friendly. It could however take weeks to dry and cure depending on the weather and applied thickness.

Boiled Linseed Oil

Boiled linseed oil contains petroleum-based and metal drying agents that accelerate the curing period but emits reactive compounds that have harmful effects.

Polymerized Linseed Oil

Polymerized linseed oil is produced by heating its raw form for several days to increase the viscosity and thickness thereby decreasing the drying time. Due to its characteristics, it is the preferred type by woodworkers and furniture makers.

To apply, clean the surfaces with a scrub brush and warm water, making sure all the dirt and debris are cleared away. After the wood dries, use a paintbrush or cloth to spread the oil evenly on all areas of the fence.

To test the cured finish, drop a small amount of water and observe if it forms a droplet, beading means the coat is sufficient. If the water disappears or is absorbed, additional oil needs to be applied.

Check out Pure Raw Linseed Oil on Amazon.

Tung Oil

Tung oil or China wood oil comes from the seeds of the tung tree found in Eastern Asia. It is a natural wood finish that has been used for thousands of years due to its distinct qualities.

Tung oil hardens when exposed to air and creates a tough transparent coat. Even in its pure untreated form, tung oil dries faster and produces a harder, more water-resistant finish. Since it is applicable in its raw, natural state, it is environment-friendly and non-toxic.

The method of application is similar to that of linseed oil. Clean, spread the substance, then test with water. Several coats are required to fully saturate and protect the wood material and yearly application will strengthen and increase the lifespan of your split-rail fence.

Check out Godora Pure Tung Oil on Amazon.

2. Wood Preservatives

Wood preservatives are chemical compounds that protect the lumber from elements and parasites that lead to degradation. They are introduced into the wood matrix through a combination of heat and pressure.

You can treat your fence by applying the same substances. Since the development of pressurized wood treatment, controversies have arisen due to the harmful effects they inflict on both health and the environment.

To avoid exposing you to hazards, the following list of preservatives contains the newest and safest formulations.

ACQ

ACQ or alkaline copper quaternary is a water-based fungicide and insecticide that is applicable for both indoor and outdoor use. Copper, which is its main component, is the most resistant metal to weathering. The compound is non-toxic and does not impact the environment.

Copper Azole

Copper azole or CA is also water-based and harmless. It is a popular choice due to its potency against fungi and insects. It has a wide variety of treatment applications for structural lumber, marine decking, beams, siding, panels, and fence posts. Copper is also its main active ingredient.

Copper Naphthenate

Copper naphthenate is a highly effective preservative that fortifies wood for heavy-duty and specialized purposes that can withstand water contact and ground exposure. They are commonly utilized for docks, piers, utility posts, and outdoor structures such as landscape timber and fence posts.

3. Woodstain Or Varnish

Woodstain is a combination of natural oil, sealants, and pigments that protect the wood from deterioration due to moisture and UV rays. They do not penetrate as deeply as oil or wood preservatives but create a surface layer that prevents environmental damage.

An optimal application would depend on the compatibility between the type of stain and the wood material.

Oil-Based Stains

The general principle is that oil is thicker and takes longer to dry than water. Due to its viscosity, oil-based stains provide a denser coat and allow the wood to absorb the stain more evenly. This results in a stronger and more durable fence that also features an attractive natural finish.

Water-Based Stains

Water-based stains are easier to apply, dry more rapidly, and do not produce fumes when used. They are health and environment friendly but generally afford less resistance and limited UV and moist protection. Since they tend to humidify rapidly, several coats are required to achieve the desired effect.

Wood Type

Based on the density or closeness of wood grains, they are categorized as either soft or hardwood. Generally, oil-based stains work better with softwood while water-based solutions are more ideal for hardwood.

Popular hardwood species used for lumber include walnut, mahogany, alder, birch, maple, oak, and ash. They have characteristically small pores between wood fibers and are best stained with water-based compounds. Natural oils are always an alternative.

Cedar and pine are softwoods that absorb large amounts of stain due to the looser configuration of their fibers. It is best to use oil-based wood stain or linseed oil. The drying and curing time between applications, however, may take longer.

How To Maintain Your Split-Rail Fence?

There are several ways to preserve your split-rail fence and prolong its use and function.

- If you are still in the planning process of construction, use factory pressure-treated lumber. They are the sturdiest and most durable since the chemical preservatives are absorbed deep into the wood.

- For existing fences, stain the wood regularly. Annual reapplication will strengthen the surface and prolong the lifespan of your enclosure. Clean, scrape debris and, if you prefer, perform light sanding to improve adhesion between the stain and wood.

- Regularly check the structure of your split-rail fence for minor damage, evidence of rotting and other signs of degradation. Replace damaged components right away since weakness in one part of the fence may trigger a domino effect that could weaken the entire structure.

In Conclusion

Traditional split-rail fences possess a natural appeal and have traditional and historical significance. Like most outdoor wooden structures, you have to maintain and protect them from the elements. The best way to accomplish this is by regularly applying treatments like oil, preservatives, and stain.

We hope you gained enough information in the article and as always, we are happy to help.

![A grass meadow and a small fence next to a small pond, How Long Does Split Rail Fence Last? [And How To Prolong Its Life]](https://fencefixation.com/wp-content/uploads/2022/06/A-grass-meadow-and-a-small-fence-next-to-a-small-pond-600x400.jpg)

![White rail fence leading along cornfield and deep blue sky. How Tall Are Split Rail Fences [Inclding 2, 3, & 4 Rail Heights]](https://fencefixation.com/wp-content/uploads/2022/06/White-rail-fence-leading-along-cornfield-and-deep-blue-sky.-How-Tall-Are-Split-Rail-Fences-Inclding-2-3-4-Rail-Heights-600x400.png)